The bike is under my skin at the moment - getting closer to getting it all together now which is a major excitement in my little head!

had some more work cancelled today and tomorrow, so instead of filling my diary up - its SHED TIME!!!!

Today's efforts:-

First up - made another start on the forward controls (finally!) drilling the stainless on my poxy little drill was a no - go so I opted for 6mm Mild steel instead. I roughed out around the shapes and tacked the 2 pieces together whileIi drilled them.

this is the 18mm drill doing the last hole for the stainless spindle to go through:-

all drilled up:-

shaped them both up with the grinder, with the last edge being the one I tacked up, so they matched

cleaned up the metal with a flapper disc and got the spindle in place ready to weld up

then welded up both sides of the spindle, and they are solid as a rock! I will need to put a gusset in place to add some more support, but this will also act as a spacer to hold the bush in the right place

I will need to get the bike rolling, so i can work all the clearances out for the exhausts etc. before they get finished.

Next up was the rear mudguard. I got it off Steve but it was in a right state, with loads of cracks and holes in it. I had attempted to weld it up in the past, but it was knackered - and all out of shape.

I decided that some drastic surgery was needed!

I marked out the offending area with some tape to get the lines right, and then marked it up with a sharpie

Carefully cut the section out with the trusty angle grinder

then I cut a replacement panel, and rolled it to match the contour of the existing metal

Picked up this long reach clamp ages ago and it was more than a bit handy when tacking it all up!

then welded it all up. you may notice that i had to slit further down the sides. Because of the various knocks and bangs it had, it was all out of shape, and this allowed me to straighten it all up.

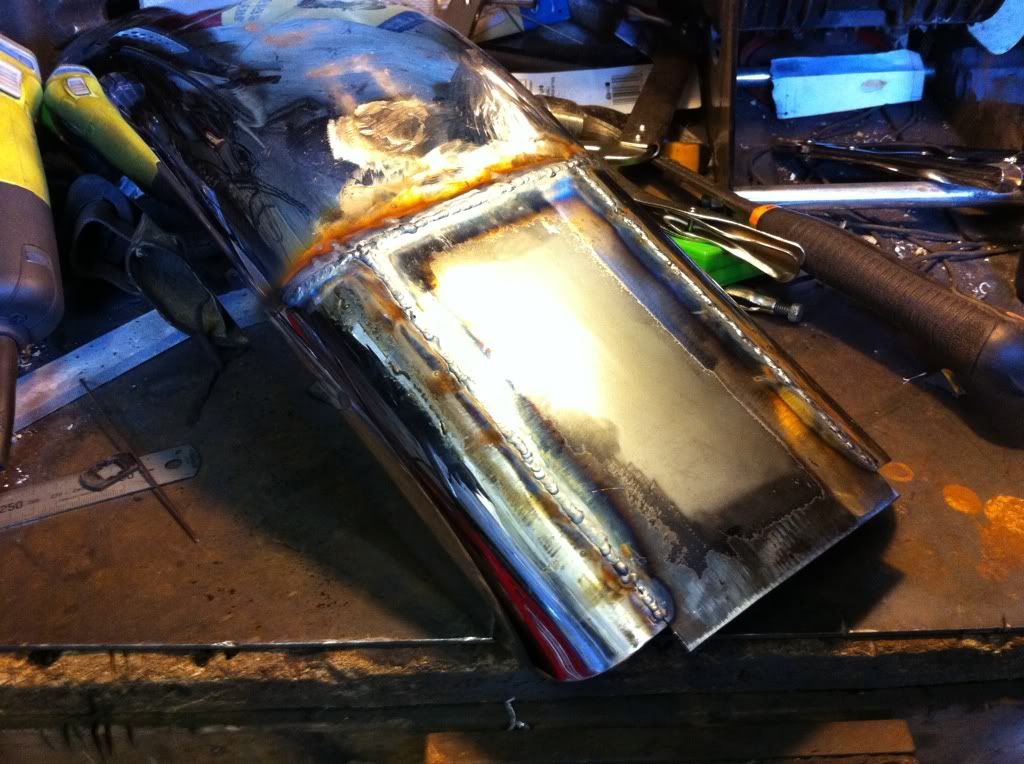

a bit of a clean up with the grinder, and it was looking alright!

The end will probably need to be trimmed, but i wont do that until its been mounted and i can see where to cut.

I then cut out for the chain to go past, and put a bit of filler on to smooth it all out.

In between tea breaks ive also been rubbing the tank down - its been giving me a bit of jip, as the primer reacted with the filler and metal. its weird, but it'll get there!

Finally - I've been having jip with the tank fitting over the cumbersome welds on the frame, so instead of trying to thin them down i decided it best to cut the buggers out and make some new "pretty" ones!

I've cut the one side out - you can see on the other side where I had to patch in a panel where the old tank mounts were.

a bit of cleaning up with a flapper disc

then I thought best to try the tank on.

It'll look far better, and a bit more "custom" (for want of a better word) when I put the new ones in. I will have to make 2 and make them meet under the frame, but I'll make them out of the 6mm plate I have left over to make sure they are good and strong.

No comments:

Post a Comment