I already had chrome bearing cups as can be seen in this picture...

Much measuring was needed to sort the rake of the headstock out, The white pole is the line of the forks, and the red mark where the spindle for the wheel will be. The flat bar on the end of the jig (attached to the bottom of the jig) will be the ground level when all is finished...

To get the flowing lines sorted it was time to get the tube bender out. Toddy has a very impressive bender bolted to the floor of the workshop. Great bit of kit it is too...

Tube was cut to length, then sanded to remove all the crap on the outside of the tube, then it was cleaned with thinners to get it as clean as possible. Toddy informs me that this it ensure that there isnt any crap that would both scratch the tube and damage the formers....

Prior to bending both the tube and the formers were suitably greased up to allow a smooth draw of the curve.

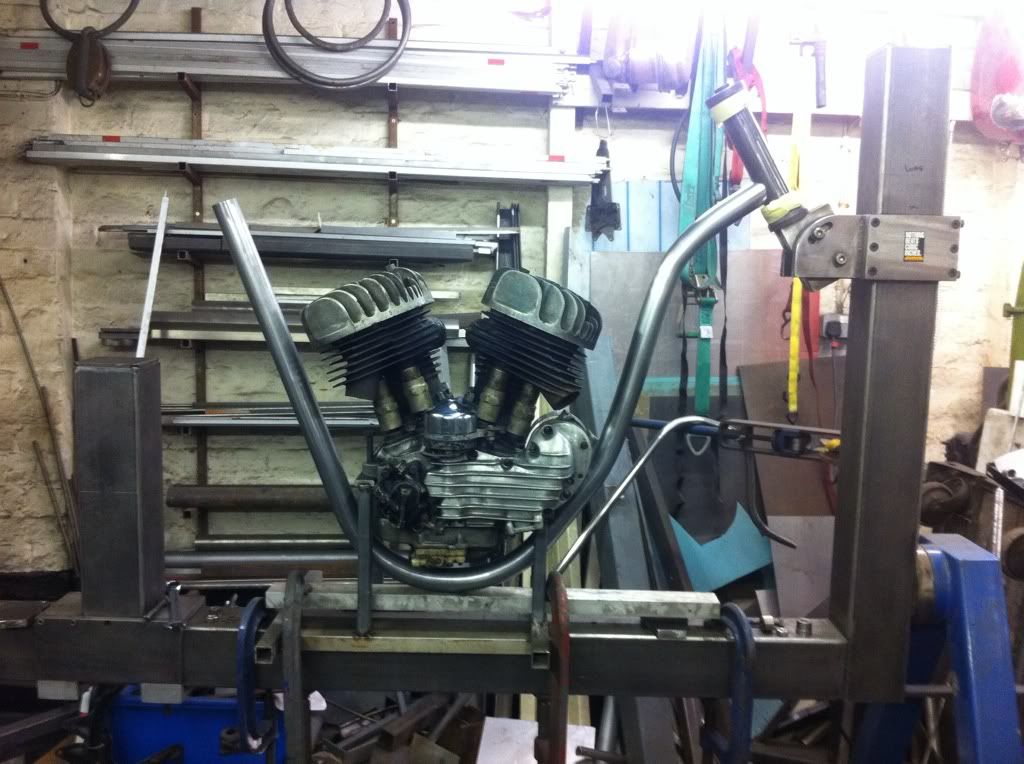

There was much tooing and froing with the tubes over to the engine in the jig throughout the day to get things right.

We started with the bottom of the engine and the big curve that would follow the crankcase.... some thin bar was used to rough the curves...

Straight tube...

and during the bend...

It went slightly over, so with some heat applied with toddys fag lighter he "relived" the bend (if thats the right word?!?)

And into the jig to see how it looked...

Now i missed some photos here, but to give the frame a nice goose neck, and to match the engine another small curve was made to kick back from the generator and then backup to headstock.

This was done loosely on the bender, and looked not bad - Toddy then refined all the curves with plenty of heat. what a difference it made to the whole look of the tube....

During this process the frame moved a bit in that it wasn't aligned down the center line of what would be the bike. Again heat and tweaking ensued to get it right.

Hopefully this picture will allow it to make a bit more sense...

The ends then had to be trimmed and profiled to meet the angles of the headstock....

and here is the bottom rail completed! another long task to get done, but well worth all the extra effort!

Next up was the top tube. The tank would cover the middle of the tube,so we decided on bending to give the desired angle to interconnect with both the headstock and the bottom tube.

The tunnel for the tank will have a V shape to sit on top,but the bend will not be visible....

This sportster tank has had the tunnel mod for another bike toddy made, so you see how the bend is not part of the look of the bike...

Final job for the day was to make a brace for the frame. The same level of care and attention was given to making this...

Again, the tank is just to mock up..

and from a different angle..

I'm absolutely stoked with how this is going. I honestly thought this would be a quicker process, but as we all know toddy doesnt do things by halves. Each curve and individual element is carefully thought through (with a fag and a cuppa), and refined until he is happy.

Hopefully you guys have an idea of the time that goes into a well thought out frame through this.

Unfortunately I have family stuff to do the next couple of days,but we'll keep putting progress of the build up as it goes.

Cheers Toddy - i'm still beaming from ear to ear!

that looks brilliant. so cool when you can work with some one who know's their shit. you just become a sponge and soak up as much knowlage as possible.

ReplyDeletefull power to your elbow.

Rob